Status

Thanks all for the patience. It was a ton of work last month keeping up with China's ever-changing rules for PPE export, but we did manage to send out just under 50 thousand masks before the bureaucrats gummed everything up and effectively shut down small shipments of PPE. We're attempting to solve the export issues that block small shipments and will open the PPE store back up if we can get shipping working again.

Quality control for the first 100 PCBAs is done. The defect rate was acceptable so I don't see any reason right now we couldn't make a larger batch next time.

100 CNC cut frames arrived and they are also through QC and checked out mostly OK.

The back covers have been modified to insert the PVD (plasma vapor deposition) coated speaker grills. The result looks good and the loudspeaker is loud enough now. It's probably fine for something like walkie-talkie mode, but the low end response leaves a lot to be desired. In later batches of phones we may look into using loudspeakers from a smartphone so that music sounds good but for now I can live with it.

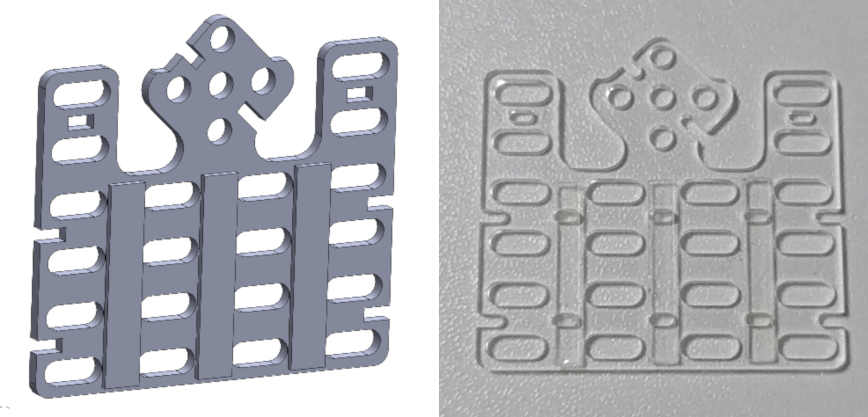

The front of the phone was a little squishy and a couple of the keys could be partially peeled out if you pried them at the right angle. Now under the silicone keypad there's a plate that helps support the front face of the phone better and locks the errant keys in place, all while acting as a light pipe for the backlit keys. The samples we have work well. 1100 of these new keypad backers are supposed to arrive on Saturday and if that happens on time we'll be assembling a batch of 100 WiPhones on Monday.

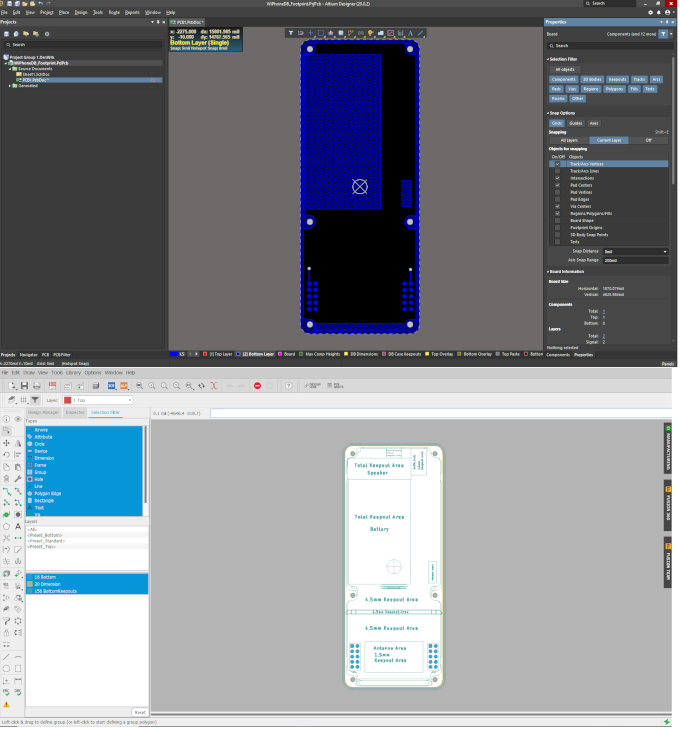

Daughterboard footprints have been posted to Github. We made footprints in Altium and Eagle. If somebody wants to make some for KiCad or other EDA tools we'll happily post them as well.

Eagle Footprint

Altium Footprint

Looking forward, once these go out I want to get all the feedback we can before we make the next batch. If you are one of the first few to get a phone please don't be shy about letting us know anyting you find wrong with them.